Computational Fabrics: When Your Sweater Becomes Your Computer

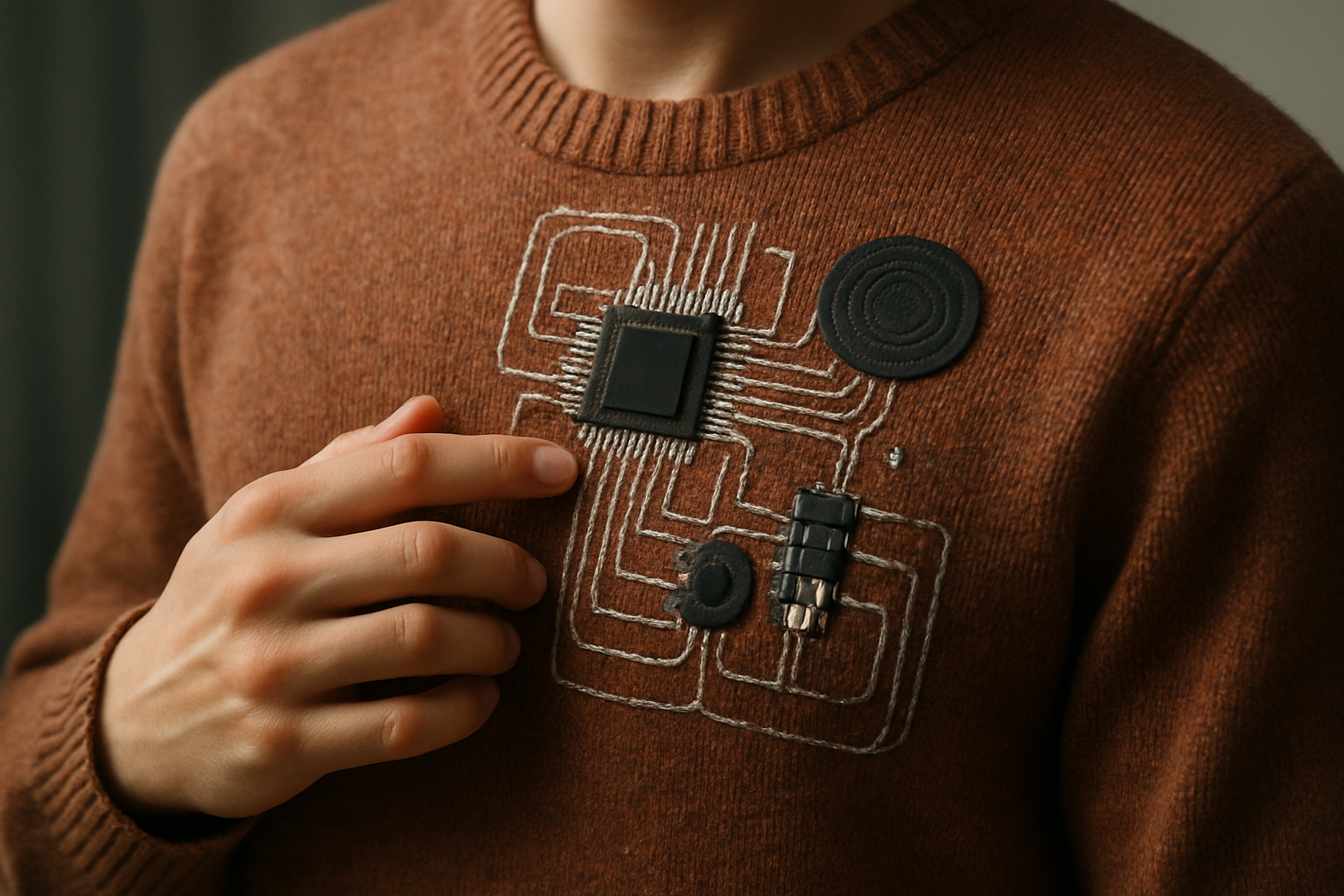

Imagine a world where the clothes on your back aren't just fashion statements, but fully functional computing devices. We're not talking about smartwatches or fitness trackers—we're entering the era where the very threads in your favorite sweater might someday run calculations, store data, or monitor your vital signs. Computational fabrics represent one of the most fascinating frontiers in wearable technology, promising to transform everyday textiles into intelligent, interactive systems that seamlessly integrate into our lives. This convergence of traditional textiles and cutting-edge computing is opening doors to applications we could only dream about a decade ago.

The threads that compute

Computational fabrics are exactly what they sound like—textiles that can perform computing functions. But unlike the rigid circuit boards inside your laptop, these fabrics maintain flexibility, comfort, and in many cases, can even be washed alongside your regular laundry. The technology relies on conductive threads that can be woven or embroidered into fabrics, creating electronic pathways that function similarly to the copper traces on traditional circuit boards.

The earliest iterations of this technology appeared around 2003 when researchers at MIT began experimenting with what they called “electronic textiles.” These primitive designs used conductive yarns integrated with simple sensors. Fast forward to today, and companies like Google (through its Project Jacquard) and academic institutions worldwide have developed sophisticated systems where touch-sensitive fibers can control smartphones, fabrics can harvest and store energy from movement, and garments can monitor everything from heart rate to posture without any external devices.

What makes computational fabrics revolutionary isn’t just the novelty—it’s their potential to dissolve the boundaries between technology and everyday objects, making computing truly ubiquitous and natural.

Beyond smart clothes: practical applications

While smart clothing is an obvious application for computational fabrics, the potential extends far beyond fitness metrics or smartphone controls. In healthcare, researchers are developing bedsheets that monitor patients’ vital signs and movement patterns, potentially preventing bedsores in immobile patients or detecting early signs of respiratory distress.

In automotive and aerospace industries, computational fabrics are being integrated into seat upholstery to detect driver fatigue or passenger comfort levels. Some advanced prototypes can even adjust heating and cooling dynamically based on body temperature readings or apply gentle pressure to different areas to improve circulation during long flights.

The military and emergency services are particularly interested in these technologies for monitoring soldier health in the field, detecting chemical or biological hazards through reactive fabrics, and potentially treating injuries through medication-delivering textiles. One prototype developed for firefighters integrates temperature sensors throughout the uniform, providing real-time heat mapping to prevent burns and identify trapped victims.

For consumer applications, the market is just beginning to explore possibilities like interactive tablecloths for restaurants that allow customers to place orders directly through the fabric surface, or curtains that adjust room lighting automatically based on time of day and occupancy.

Technical challenges of soft computing

Creating computers out of cloth isn’t without significant challenges. Traditional electronics are built on rigid substrates for good reason—flexibility puts tremendous stress on connections and components. When a computational fabric stretches, bends, and twists during normal wear, maintaining electrical connections becomes exponentially more difficult.

Power management presents another significant hurdle. While some computational fabrics incorporate energy harvesting from movement or body heat, these sources typically generate minimal power—often insufficient for anything beyond basic sensing functions. More complex computing requires batteries, which reintroduces rigidity and weight that designers are trying to eliminate.

Washability remains the holy grail for consumer applications. While some current systems can withstand gentle cleaning, most require removal of key components before laundering. Creating truly washable circuits that can withstand detergents, water immersion, and the mechanical action of washing machines represents one of the field’s most active research areas.

Perhaps most challenging is the manufacturing scale-up. Traditional textile production is highly optimized for cost and speed, while electronics manufacturing prioritizes precision and cleanliness. Bridging these two industries requires entirely new production methods and quality control systems.

The commercial landscape takes shape

Despite these challenges, several companies are bringing computational fabrics to market. Pricing remains premium—with smart garments typically costing 3-5 times their non-computational counterparts—but the industry is seeing steady growth. Market analysts project the smart textile industry will reach approximately $9.3 billion by 2024, up from about $2.7 billion in 2019.

Google and Levi’s Jacquard-enabled trucker jacket, now in its second generation, retails around $198 and allows wearers to control music, navigation, and call functions through subtle gestures. SKIIN, a Canadian startup, offers undergarments with integrated biometric monitoring starting at $279 for a starter kit, positioning their products as wellness tools rather than mere gadgets.

In the industrial sector, companies like DuPont and their Electronic Materials division are developing specialized conductive inks and materials specifically for textile applications, indicating growing infrastructure investment in this emerging field.

Perhaps most telling is the entry of major semiconductor companies like Texas Instruments and ARM into the space, with both developing ultra-low-power microcontrollers and reference designs specifically for textile integration.

The computational wardrobe of tomorrow

Looking ahead, computational fabrics will likely follow the classic technology adoption curve—moving from specialized, expensive applications toward mainstream consumer products as manufacturing techniques improve and costs decrease.

Within five years, we’ll likely see standardization in conductive thread interfaces and programming environments, much like how USB and common coding languages standardized traditional computing. This standardization will accelerate development and bring prices down significantly.

The true breakthrough will come when computational elements become invisible components of everyday garments rather than special features. Imagine buying a regular-looking T-shirt that happens to monitor your heart rhythm, or purchasing curtains that naturally regulate room temperature without any visible technology.

As with most emerging technologies, the killer applications may be ones we haven’t even conceived yet. The history of computing shows that placing powerful tools in the hands of creative people leads to innovations beyond the imagination of the original inventors. When your jacket becomes as programmable as your phone, what will you make it do?

The fabric of computing is quite literally changing, weaving new possibilities into the very clothes we wear. As these technologies mature from research curiosities to practical products, they promise to transform not just how we interact with computers, but how we think about what a computer is in the first place.